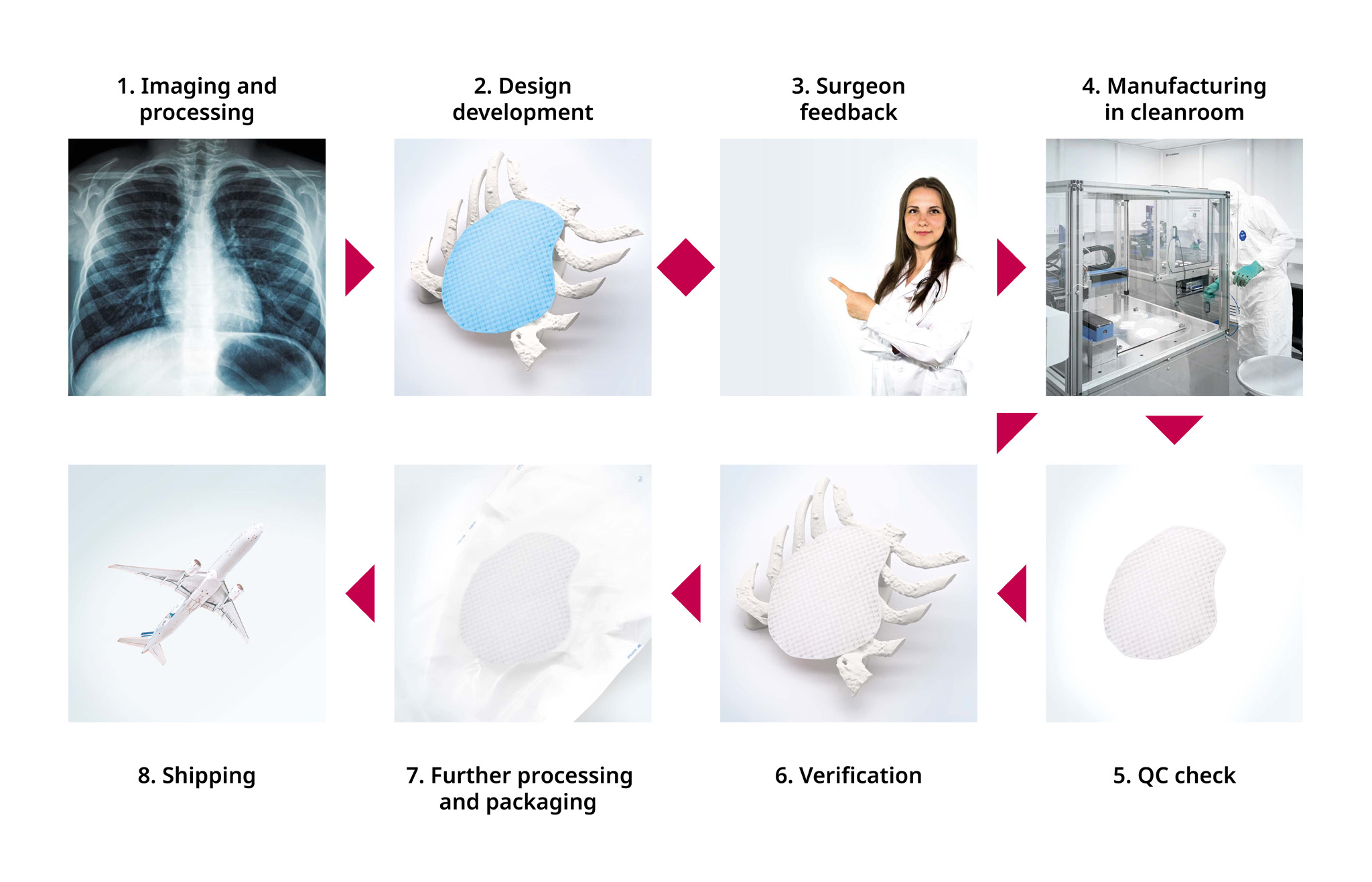

How it works

1. Imaging and processing

CT scan/MRI of the patient’s breastbone deformity is provided by the surgeon to BellaSeno. A 3D-model of the breastbone/chest deformation will be generated from the 2-dimensional scan CT/MRI images.

2. Design development

A virtual and physical patient-specific 3D-model of the PCL pectus scaffold will be generated via the 3D breastbone deformity model in step 1 using a 3D modelling software application to fit the defect and correct the patient’s specific congenital deformity. Steps 1 through 2 will generate a custom-made or patient specific single use scaffold for each patient.

3. Surgeon feedback

A feedback loop on the 3D-model of the patient specific PCL pectus scaffold is collected from the surgeon in-person or virtually to ensure that the scaffold specifications (e.g., dimensions and stiffness) meet the surgeon´s and ultimately the specific requirements of the patient´s chest deformity to optimize the repair and hence the clinical outcome.

4. Manufacturing in cleanroom

Once the PCL pectus scaffold design has been approved by the surgeon, it is then produced using additive manufacturing (AM) within an ISO 14644-1:2015 Class 7 (federal standard 209E equivalent, and associated EU GMP grade: C) cleanroom via validated, medical-grade additive manufacturing equipment under the supervision of highly trained personnel.

5. QC check

The quality team performs the preliminary relevant quality checks on each approved PCL pectus scaffold which include, but not limited to dimensions and mechanical properties.

6. Verification

Verification activities are performed prior to shipping each patient specific PCL pectus scaffold to be implanted. Verification activities predominantly include the scaffold´s ability to fully fit the deformity volume, area coverage projection and confluence with the adjacent rib cage either side of the sternum utilizing the breastbone or chest deformity model produced via the CT/MRI scans.

7. Further processing and packaging

The PCL pectus scaffold patient-specific scaffold for implantation is sent to BellaSeno qualified subcontractors for validated/automated oxygen plasma cleaning and validated sterilization within validated double blister packaging with humidity and sterility preserving seals. This is a standard process used in medical device industry. Plasma cleaning process is performed in an ISO Class 8 cleanroom by trained personnel based on a validated process. Packaging process is performed in an ISO Class 7 cleanroom by trained personnel based on validated process.

8. Shipping

The quality team performs the final relevant quality checks and approved PCL pectus scaffold is then shipped to the surgeon.