By leveraging complex unit-cell architectures, high-speed additive manufacturing and clinically proven materials, we are redefining the possibilities of scaffold architecture, aesthetics, performance, and scalability.

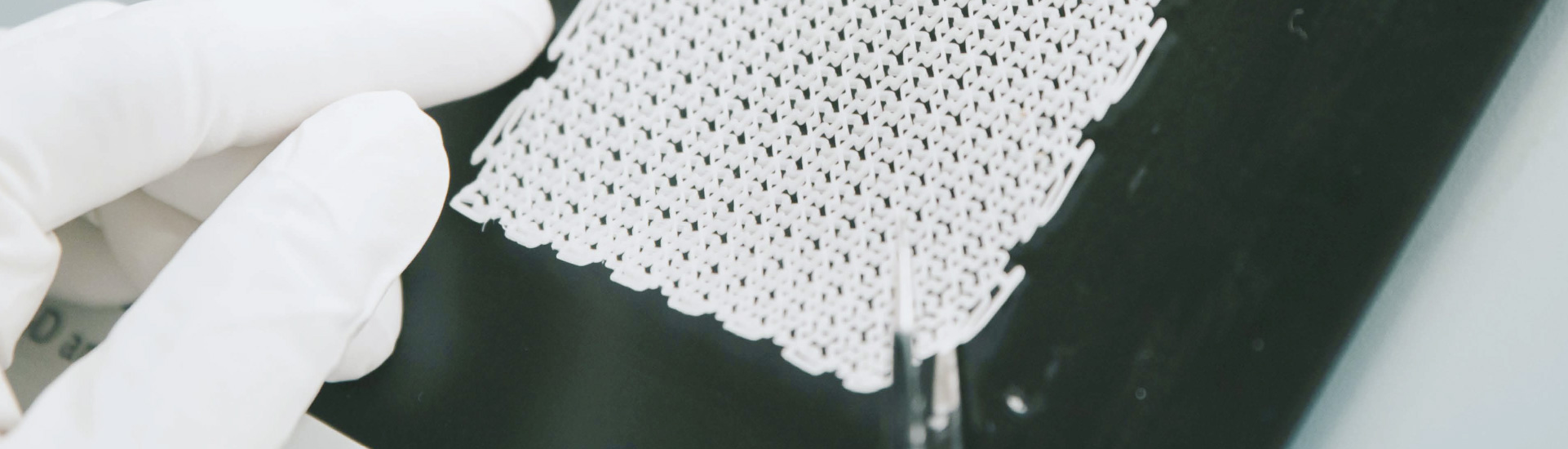

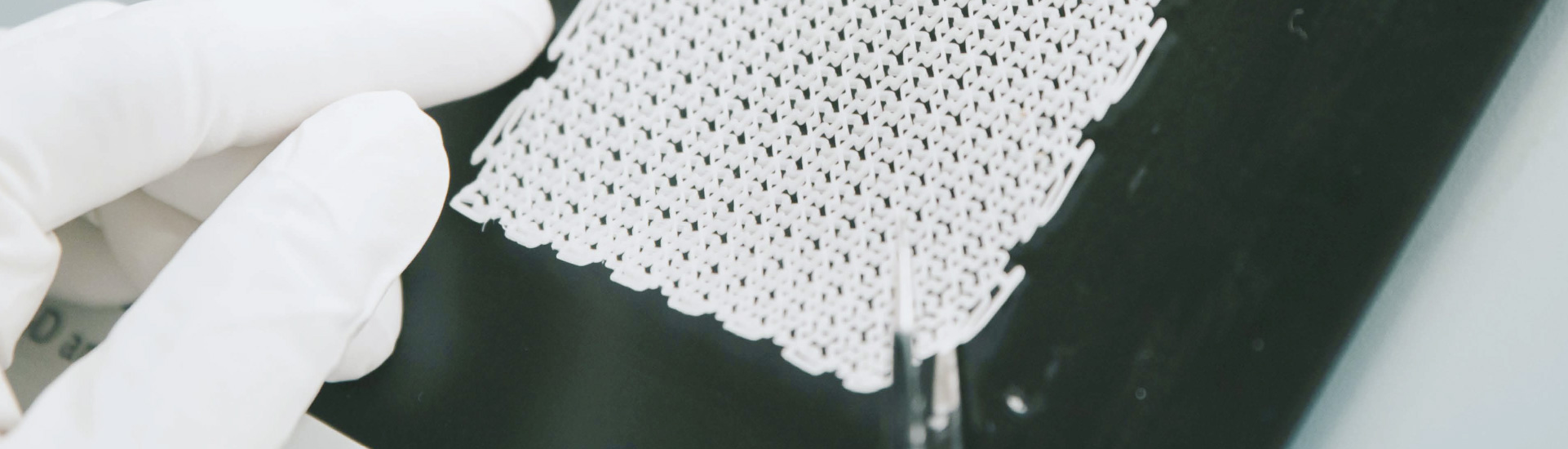

Enabled by our custom design software, the 3D unit-cell based architectures optimize strength and flexibility. Fully open porous design enables full integration of the implant into the body (i.e. no encapsulation) and vascularization at the regeneration site.

Additive manufacturing provides full flexibility in product range—off-the-shelf, mass personalized or fully custom-made scaffolds.

Used in unprecedented ways to achieve new levels of safety and performance at scale:

We are building the world’s first AI-driven additive manufacturing facilities based on the so-called no-touch approach: intelligent software and robotics to significantly improve the safety and sterility of medical implants.

ISO-13485 certification, repeatable process, reliable equipment and end-to-end GMP-grade supply chains.